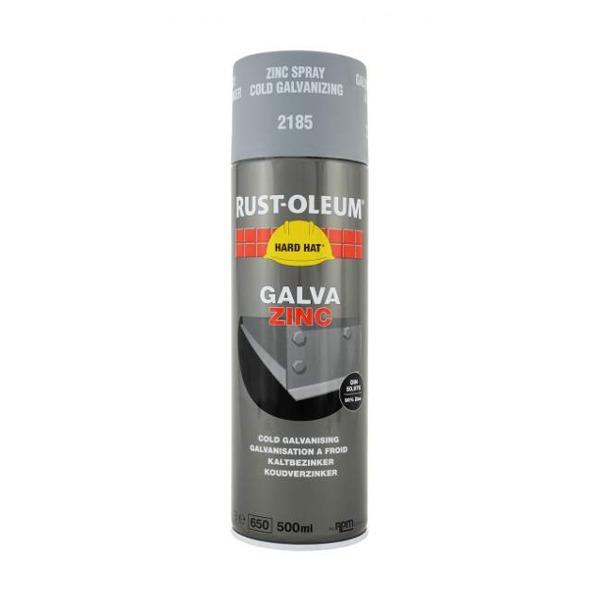

Rustoleum 500ml Aerosol 2185 Galva Zinc

Availability:

in stock, ready to be shipped

Original price

£18.60

-

Original price

£18.60

Original price

£18.60

£18.60

-

£18.60

Current price

£18.60

Details: